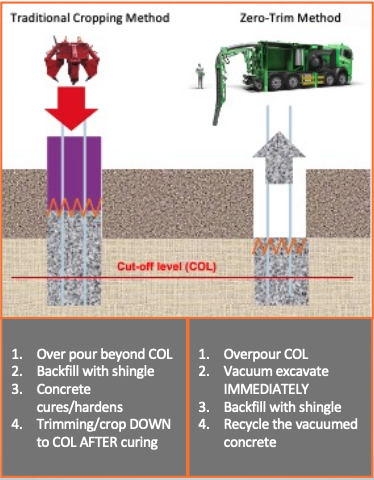

Traditionally, piles are trimmed or broken using percussive breaking or a cropping method such as Elliott, but this is time consuming and costly and results in damage to the projecting reinforcement. The established methods also have potentially very significant health and environmental impacts.

In late 2020, Hercules worked with the Skanska Costain Strabag Team to devise a method of pile reduction that means there is little or no physical breaking required. The method involves the reduction of the pile caps when the concrete is wet using a suction excavator to easily reduce the pile to the correct height.

In order to demonstrate that the method meets the CIE Specification for Piling and Embedded Retaining Walls (SPERWall) and be approved, a trial was carried out in November 2020 by Hercules to demonstrate that the method was workable and maintains the pile integrity. The trials clearly demonstrated that the suction excavator has the capability to remove freshly poured concrete from a pile bore. The process easily removed the excess concrete from the annulus between the cage and the ‘casing’ and has minor impact on the piling process/duration as demonstrated it takes a matter of minutes to remove the excess concrete and polymer. The method reduced the amount of pile trimming to virtually ZERO and has been called a “game-changer’ within the industry.

Savings of £374k

Approx. 1700 piles in total Area East

60,000 working hours (breaking) saved

- No repair on reinforcement needed

- No noise from drilling and breaking – reduced risks to workforce and stakeholders

- No lifting of equipment required

- H&S risks associated with hand cropping eliminated – HAVS, confined spave, silicosis, working at height

- Integrating capping beam reinforcement made easier

- Benefit of Suc Ex for other high risk utilities activities

- Increased accuracy in achieving cut of level